The Need: Operation and Maintenance (O&M) of offshore wind farms (OWF) and oil and gas (O&G) fields must maintain the integrity and protection of their subsea cable, flowlines and foundation infrastructure over the 20+ year (O&M) lifecycle. Massive OWF expansion is in the pipeline.

The Need: Operation and Maintenance (O&M) of offshore wind farms (OWF) and oil and gas (O&G) fields must maintain the integrity and protection of their subsea cable, flowlines and foundation infrastructure over the 20+ year (O&M) lifecycle. Massive OWF expansion is in the pipeline.

Action: Contact us to discuss cost-effective solutions for existing and ongoing survey needs. Send request for proposals (RFPs) and requests for quotes (RFQs) to: info@ipsubsea.com

The Problem: Once offshore installations have transitioned from construction to O&M phase, operators are often constrained by tight budgets and limited staff. Periodic survey of subsea assets is a vital measure that often gets delayed or overlooked. Proper preventive maintenance is a low cost alternative to costly maintenance and repair operations. Conventional survey methods can be:

- Costly due to specialty vessels, sensor technology and many skilled operators.

- Problematic or impractical when comparing historical data from different survey contractors used over time

- Put-off or neglected reducing the frequency of up-to-date data

- Incompatible with previous and ongoing survey data

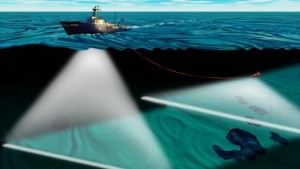

The Solution: Autonomous underwater vehicle (AUV) and autonomous surface vessel

(ASV) technology enables cost-effective O&M lifecycle survey of offshore infrastructure like; foundations, platforms, array cables, export cables, and pipelines. Unmanned and autonomous vehicle platforms can be pre-programmed with infrastructure waypoints and cable routes. The process of transiting to the site and tracking along cable routs can be automated removing human error and costly man-hours of support. Both platforms share many of the benefits over conventional survey technology. AUV/ASV platform technology provides a lower service price-point resulting from cost-benefits through:

- Cost-competitive vessel day rates

- Multiple ASV concurrent ops

- Lower fuel usage/costs

- Smaller vessel platforms

- Automation lowering crew requirements

- Small operational support teams

- Schedule flexibility

- Single shallow to deep solution

- Minimized mobilization and demobilization costs

Direct Operator Benefits: While AUV/ASV technology provides breakthrough cost reductions, the added value of a comprehensive survey strategy provides owners and operators with other tangible benefits including:

- Budget friendly maintenance survey strategy

- Early identification of production threats or “hits”

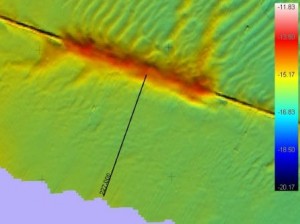

- Early identification of remedial burial needs due to seabed migration

- Scour and subsea foundation condition monitoring

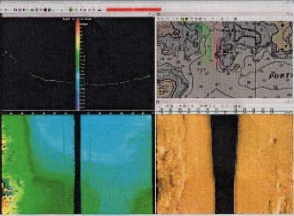

- Ongoing up-to-date monitoring with layered historical data

- Early detection of mobile sediment and transfer risk

- Consistent high quality year-over-year visibility

- Environmentally friendly low fuel usage

- Reduce or eliminate M&R mob charges and emergency premiums

- Opportunistic contracting of ‘fly-by’ maintenance and repair (M&R) services from providers like:

AUV/ASV Survey costs are reduced significantly compared to conventional survey vessel solutions. More frequent periodic inspections identify and track progressive changes in seabed migration, exposed cable, foundation scour and degradation as well as damage from external “hits” like anchors and fishing activity. As periodic survey costs come down, inspection frequency can increase providing:

- Attractive long-term service options

- Comprehensive condition monitoring strategy

- layered historical data accumulated with each survey

- Up-to-date subsea condition visibility

- Variety in sensor payload technology

- Reduce or “head-off” costly repairs and maintain asset valuations

Operational Partners:

Phoenix International : International Marine Contractor, AUV/ROV Owner, Operational support, Logistical Support

Phoenix International : International Marine Contractor, AUV/ROV Owner, Operational support, Logistical Support

“Phoenix International is an experienced marine services contractor providing underwater engineering and operational solutions to customer requirements worldwide. We are committed to ensuring the safety of our personnel at all times; our excellent safety record is a testimonial to the success of this commitment.”

Maritime Applied Physics Corporation : ASV Design, Build, Testing, Production and support

Maritime Applied Physics Corporation : ASV Design, Build, Testing, Production and support

“MAPC transitions technologies to production. We excel at mechanical and electrical system design, complex and thorough program management, military standard environmental testing, and development of technical data and documentation packages. Our reputation has been built on finding robust solutions to formidable engineering problems in challenging environments, often more quickly than expected. Hot, cold, rugged, deep, remote – wherever you want to put your system, let us find a way.”

Action: Contact us to discuss cost-effective solutions for existing and ongoing survey needs. Send request for proposals (RFPs) and requests for quotes (RFQs) to: info@ipsubsea.com